News

UBloks Excellent Engineering Case Selection Results Announced

May 01, 2025

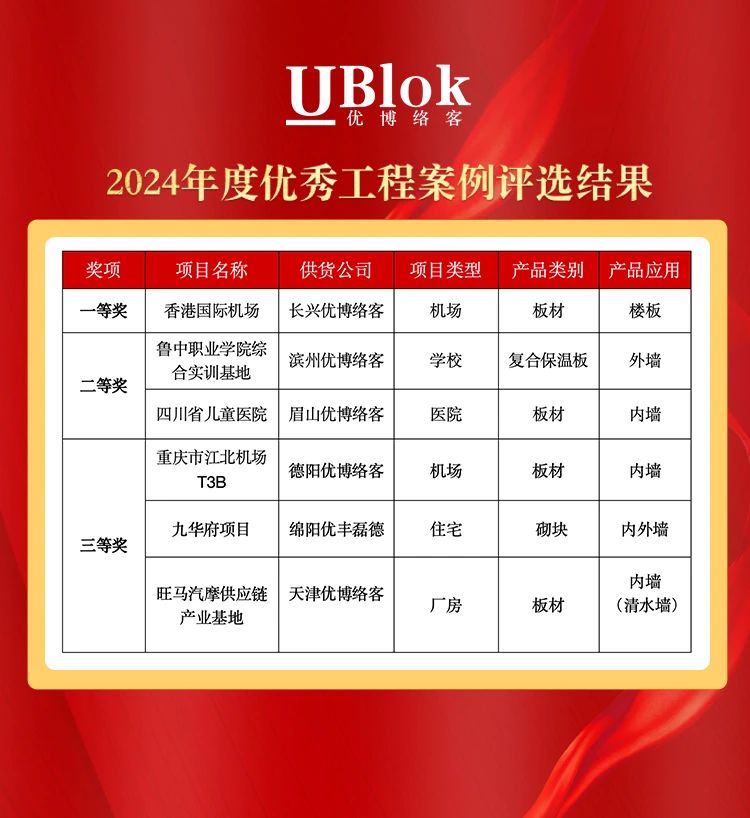

In 2024, with the joint efforts and witness of all partners, the production and sales volume of UBlok exceeded 6 million cubic meters for the first time, reaching a new historical high. Among them, there are quite a number of outstanding engineering cases with certain representativeness and influence. This solicitation activity for outstanding engineering cases has received enthusiastic contributions and strong support from partners. Through strict screening in terms of project scale, technical difficulty, and project influence, a total of 16 outstanding engineering cases were shortlisted. Through a combination of online voting and offline evaluation, first, second, and third - prize projects were comprehensively selected. Now, the selection results are announced as follows:

First Prize: Hong Kong International Airport

Project Overview:

The expansion project of Terminal 2 of Hong Kong International Airport is an important part of the Hong Kong Three - Runway System project and also the airport expansion project with the largest investment scale in the history of China's civil aviation. The construction area of the project is 310,000㎡, and it has won the "BEAM Plus New Buildings Version 1.2 Provisional Platinum" certification, which is the highest rating of the Hong Kong Green Building Council's assessment program.

Introduction to Product Application:

For the expansion of Terminal 2 of the airport, the commercial center area has a steel - structure system. YTONG AAC floor slabs (with a thickness of 150mm) were selected. Conservatively estimated, the installation efficiency of YTONG AAC floor slabs has increased by 40% compared with the original design plan, greatly shortening the construction period.

As there are a large number of mechanical and electrical pipelines, exhaust ducts, fire - fighting pipes and other facilities and equipment at the airport, which require cross - cooperation and reserved holes. Compared with concrete structures or metal - concrete composite boards, AAC floor slabs can be more flexible in reserving and coordinating the construction of mechanical, electrical and fire - fighting projects, while reducing a large amount of unnecessary rework and material loss.

Compared with other solutions, in terms of material entry, AAC products are relatively light in weight and can be operated through manned freight elevators and tower cranes, which is convenient for vertical and horizontal transportation.

Second Prize: Comprehensive Training Base of Luzhong Vocational College

Project Overview:

It is located in Zouping City, Binzhou City, with a construction area of 12,370㎡. The project has won the honorary title of "Safety Standardization Learning and Exchange Project for Construction in East China Region".

Introduction to Product Application:

According to the current building energy - saving standard in Shandong Province, which requires reaching 83%, prefabricated AAC composite thermal - insulation exterior wall panels are adopted. These panels have excellent thermal performance, light self - weight, fire - resistance, and are convenient for construction. AAC composite thermal - insulation exterior wall panels are pre - assembled on a mechanical automated production line in the factory, ensuring product quality, reducing wet - work links, and the on - site prefabricated installation method has also greatly improved the construction efficiency.

Second Prize: Sichuan Children's Hospital

Project Overview:

It is located in Meishan City, Sichuan Province, with a construction area of 154,200㎡. It is the first national - level regional medical center approved for construction in Sichuan Province and also the only provincial children's hospital in China that is located in a prefecture - level city instead of the provincial capital city.

Introduction to Product Application:

AAC boards have a low density. Compared with traditional masonry materials, they can effectively reduce the overall weight of the building. For a large - scale building like Sichuan Children's Hospital, it can reduce the load on the foundation and structure parts, reduce the consumption of materials such as steel bars and concrete, save construction costs, and at the same time improve the seismic performance of the building, providing a safer guarantee for children patients and medical staff.

Hospitals have extremely high requirements for hygiene and environmental protection. The selection of environmentally friendly and non - toxic AAC boards can ensure indoor air quality and environmental hygiene, creating a comfortable medical environment for children patients and meeting the hospital's energy - saving and environmental - protection requirements.

Third Prize: Chongqing Jiangbei Airport T3B

Project Overview:

It is located in Yubei District, Chongqing City, with a construction area of 360,000㎡. The project innovatively introduced a monorail rapid transit system, which is the world's first straddle - type monorail solution customized for an airport.

Introduction to Product Application:

The basement foundation structure is complex: The APM monorail track foundation structure is located on the first basement floor of the terminal building and intersects with the pipe gallery on the second basement floor, resulting in great construction difficulty. The specifications of AAC interior wall panels are relatively uniform and can be cut and processed according to design requirements, which is convenient for installation. It can better meet the requirements for the installation accuracy of walls in the complex spatial layout of the airport building, helping to ensure the verticality and flatness of the walls and improving the overall aesthetics.

The mechanical and electrical installation is complex: The terminal building adopts the design concept of "a roc spreading its wings, ready to soar", with a unique architectural shape, numerous large and small spaces, and a complex mechanical and electrical system, which poses challenges to mechanical and electrical installation. Especially, the approximately 2.6 - kilometer small - arc curved pipeline along the four finger corridors cannot meet the construction requirements with traditional processes. AAC interior wall panels are easy to drill and groove, which is convenient for installing various mechanical and electrical equipment, pipelines and decorative components on the wall. It is convenient to cooperate with the pipeline layout of complex mechanical and electrical equipment, fire - fighting systems, ventilation systems, etc. in the airport. Precise reservation and grooving can be carried out in advance to ensure the passage of pipelines, and good sealing and reinforcement can be done to prevent problems such as wall leakage and cracking.

Third Prize: Jiuhuafu Project

Project Overview:

It is located in Fucheng District, Mianyang City, with a construction area of 1,620,000㎡. It is a high - end residential complex built by Mianyang City for high - end talents of the China Academy of Engineering Physics, a national major special - project supporting project, and a key part of the construction of Mianyang Science City.

Introduction to Product Application:

As a high - end residential complex, the Jiuhuafu project has extremely high requirements for anti - leakage and anti - cracking of interior and exterior walls. AAC blocks have a small dry - shrinkage value and good bonding performance with the plastering layer, which can reduce the generation of cracks in interior and exterior walls to a certain extent. At the same time, at the joints between AAC block walls and concrete beams, columns and other different materials, appropriate and reinforcement measures are taken to effectively reduce the risk of cracks caused by material deformation differences.

The project requires full - delivery, with high requirements for the construction quality of interior and exterior walls. The flatness, verticality of the wall surface and the squareness of the internal and external corners need to be strictly controlled. AAC blocks have a high surface flatness, with a mortar joint of 3mm - 5mm. Only a thin plastering on the surface can ensure the flatness accuracy of the wall surface, while avoiding problems such as wall hollowing, cracking and cold bridges.

Third Prize: Wangma Auto - Motorcycle Supply Chain Industrial Base

Project Overview:

It is located in Mafang Town, Pinggu District, Beijing, with a construction area of 122,974.63㎡. The project adopts a fair - faced wall design, which not only meets the functional requirements of industrial buildings but also improves the architectural aesthetics.

Introduction to Product Application:

AAC fair - faced walls can be flexibly cut and installed according to different functional requirements to achieve flexible space separation. The selection of AAC fair - faced walls can effectively reduce the self - weight of the building and the structural load, especially in some areas sensitive to load, such as high - rise shelf areas or large - span spaces, which helps to improve the safety and stability of the structure and can also reduce the cost of the foundation project. The surface of AAC fair - faced walls is flat and smooth, with a consistent color, and does not require additional decoration, having a unique simple aesthetic feeling, which can create an industrial architectural style for the industrial base. At the same time, it has good durability and a long service life, reducing the later maintenance cost.

This selection activity for outstanding engineering cases has been successfully completed. In the future, UBlok will continue to lead the enterprise development with the strategy of "low - carbon, intelligent, and international", and with a transformative mindset, innovative concepts and a pragmatic style, apply more of UBlok's "good products" to more "good houses", jointly promoting the transformation and development of the construction industry.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor